An affiliate of Ulysse Nardin and Mimotec, Sigatec specialises in silicium micro-mechanical components and creates custom-made pieces with micron-level precision.

Silicium is a metalloid, a type of chemical element that resembles metal without possessing all of its properties, in particular its hardness. Its usage has been generally applied in the sector that mainly manufactures semi-conductors, transistors and microprocessors, which uses the material as a base for etching micro and integrated circuits. It presents a series of properties that make it perfectly suitable for use in micromechanical precision, a field that includes watchmaking.

Since the early 2000’s, Silicium has become the most promising material in watchmaking.

The Material

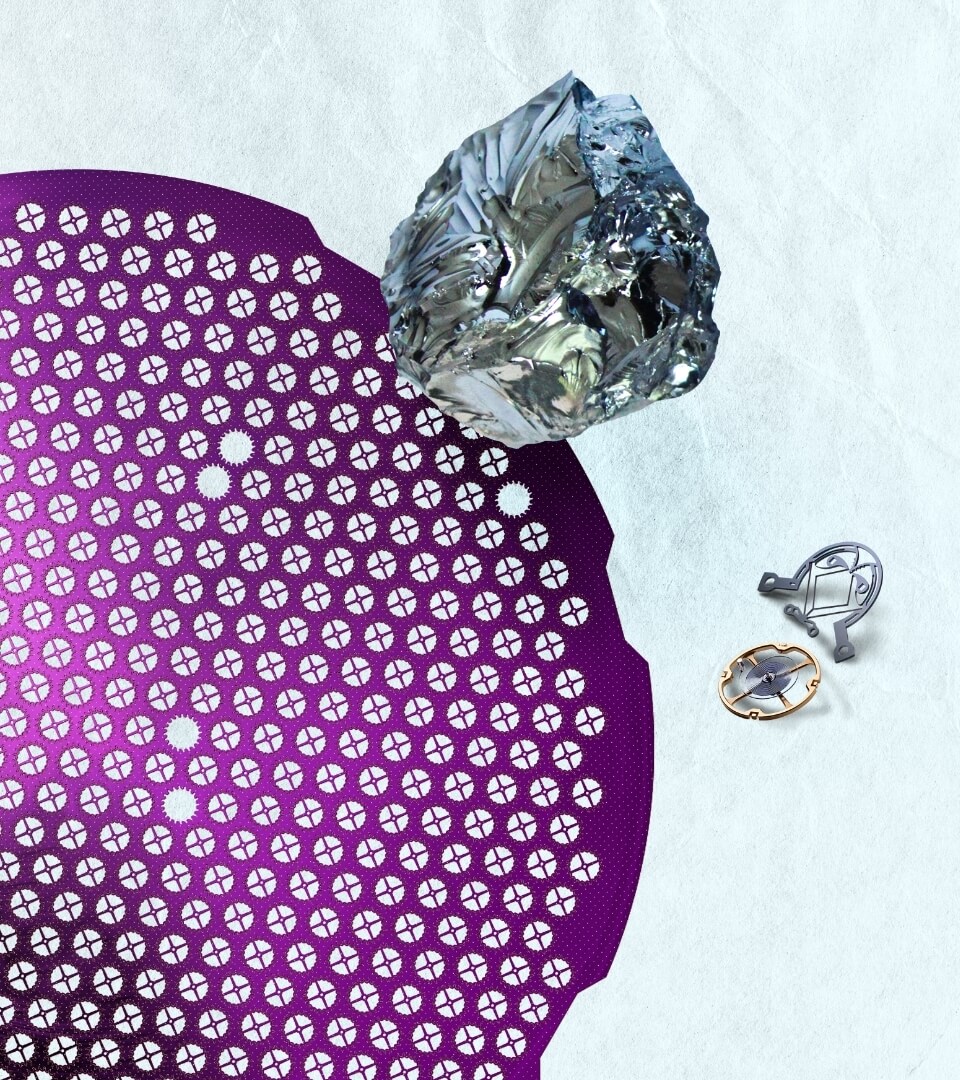

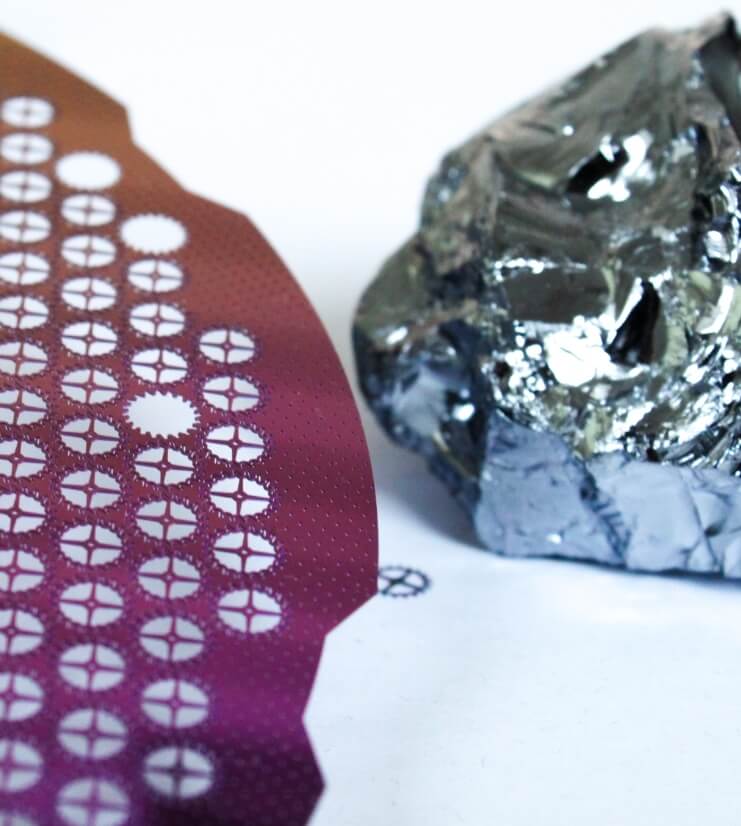

The silicium used by Sigatec comes in the form of a wafer, a disc about 15 centimetres in diameter and only a few tenths millimetres thick. Carved out of a silicon crystal ingot, produced synthetically by smelters. The biggest ingots can measure up to two meters high and are made of a single crystal, which guarantees a perfectly homogenous and first-rate material. These smelters cut and polish the silicium crystal into wafers and deliver these intermediary parts ready for machining. They cost several hundred francs. The cost of the material remains this way only due to the high-technicality work involved.

DRIE

Silicium necessitates a particular process in order to be formed into the desired components. DRIE, or Deep Reactive Ion Etching, has, in only just 10 years, conquered its own place in watchmaking. The space in which this process takes place is extremely important in determining the final result. Silicium is made in a cleanroom, just like microprocessors. In order to enter the space where Sigatec has its main operations, everyone needs to wear specific equipment that protects the workshops. In a pressurised air chamber, each particle suspended in the air, on your skin, clothes, hair or beard is vacuumed or enclosed behind a barrier made of synthetic and antistatic fabric.

Ions and plasma

What follows is the deep engraving phase, or etching. In two plasma machines that look like a compact chemical reactor and cost a million francs per unit, the wafer bearing the geometric shapes for the desired components is inserted. A near-total empty air vacuum reigns in the confined tank, similar to that of outer space. Several fluids are inserted in succession. The first is a plasma that targets the silicium, dissolving the areas not protected by the mask. After removing a third of a micron, the plasma is purged from the tank. A passivation layer is injected, which is a polymer that covers the entire engraved surface, including the sides and bases. The base is then destroyed with ion bombardment so the plasma process can be applied again. This way, in a succession of micro-layering, silicium reaches the desired thickness. It’s this process that is the core of the Bosch patent utilised and mastered by Sigatec.

Multileveled

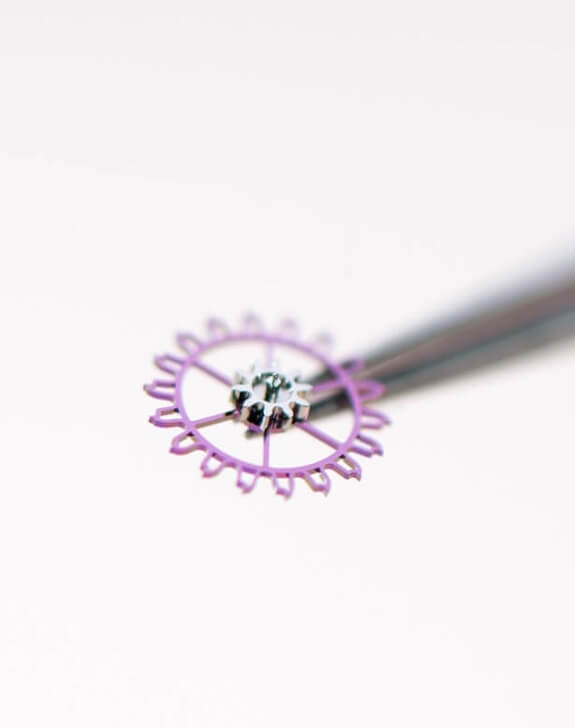

In order to obtain these complex pieces, in several levels, a number of masks can be applied on the same wafer at different stages of manufacturing. The wafers are then removed from the plasma machine, irradiated through a new mask and re-inserted into the etching machine. In every case, the geometry obtained shows a precision of ±2 microns. In reality, the etching isn’t exactly three dimensional, but 2.5D as the geometric shape on the mask is projected in the engraving process. Sigatec masters DRIE chamfering, which intervenes separately, once the pieces are etched. Moreover, one of the latest innovations from Sigatec is welding on these micro-pieces. On selected points of contact, it is now possible to create a fusion between two surfaces with the help of silicium oxide. The oxide is created by injecting oxygen at high temperatures in a reaction oven.

It allows the manufacturer to obtain monobloc components with complex shapes, like a puzzle with many layered pieces.

The Finishing

Once the wafer is etched, the remaining epoxy resin is removed. Now comes the last step of the production process. In an oven filled with gases and heated to certain temperatures that will remain a secret, a layer of silicium dioxide forms on the surface of the components. This hardens the pieces as well as achieving the sought-after stability in the face of thermal variations. Indeed, the silicium’s modulus elasticity is lowered as temperatures rise (like with most materials) while the silicium dioxide only gets stronger. This composite of the two materials therefore has a modulus elasticity that is practically indifferent to variations in temperature. It’s also at this stage that the components take on their final colouring, varying from bright purple to a slate grey. The finished components are then separated from the base wafer with a process involving acid etching.

The Options

As an added option, the fi nished silicium components can be coated with a layer of monocrystalline diamond. In a machine with several light beams, Sigatec lays, layer by layer, pure carbon crystal in a cubic structure—in other words, diamond! This allows them to increase the hardness of the pieces and adds an element of specifi city and personalisation representative of Sigatec’s custommade processes.

The Energy Outcome

DRIE consumes large quantities of energy. The air fi ltration. The bath treatments. The temperature management. The consumption of energy for the ovens, the etching machines. That of the plasma machines and their turbos that allow for an air vacuum. Sigatec therefore created a geothermal borehole in order to minimise with energy consumption and to reduce its impact on the environment.